Today, pneumatic conveying systems, which stand out among industrial conveying solutions, offer an efficient and economical option, especially for powder and granule conveying systems. Establishing a pneumatic conveying factory can be a highly profitable venture for industrial investors and factory investors. However, the process of establishing a pneumatic conveying system manufacturing factory requires careful planning and the right investments. In this article, we will cover everything you need to know about pneumatic conveying systems manufacturing in detail! 📌

İçindekiler

ToggleWhat is Pneumatic Conveying and Why is it Preferred? 🤔

Pneumatic conveying is a highly efficient system that allows materials to be transported from one point to another using air pressure or vacuum. These systems are used in many areas such as cement conveying systems, plastic granule conveying systems, food sector pneumatic conveying solutions and chemical industry pneumatic conveying.

Advantages of Pneumatic Conveying Systems:

✅ Requires less maintenance – Pneumatic conveying systems have fewer moving parts compared to mechanical conveying systems.

✅ Closed system – It offers hygienic transportation by preventing dust and dirt formation.

✅ Flexible and modular structure – Pneumatic pipe transportation systems can be easily expanded and adapted to production lines.

If you are thinking of establishing a factory that offers industrial transportation solutions, establishing a pneumatic transportation factory can be a profitable investment for you! 💰

What is Required to Establish a Pneumatic Conveying System Manufacturing Factory 🏗️

To establish a pneumatic conveying systems factory, provide system integration and produce industrial pneumatic solutions, you must follow the steps below:

1️⃣ Factory Location Selection and Licensing 🏭

📌 Pneumatic conveying systems licensing and legal requirements depend on the location of the factory to be built. From a logistics and warehouse management perspective, it is important to choose a location that is easy to access.

Adapte Dijital’in 10 yıllık deneyimiyle geliştirilen bu model, kurumsal web sitenizi sadece tasarlamakla kalmaz;

onu data toplayan, talep yaratan, kurumsal iletişim sağlayan bir dijital yönetim altyapısına dönüştürür.

Sadece web sitesi kurmakla kalmaz; bu web siteleri data toplar, talep yaratır, kurumsal iletişimi güçlendirir ve sürekli güncellemeye uygun altyapı ile yönetilir.

2️⃣ Required Equipment and Machinery ⚙️

You will need the following equipment for the installation of pneumatic conveying systems:

🔹 Pneumatic conveying systems🔹 Vacuum conveying systems

🔹 Pneumatic conveying pipe systems

🔹 Filtering for powder and granule conveying systems units

3️⃣ Investment Cost and Profitability 📈

Pneumatic conveying systems investment cost varies depending on the technology used and capacity. However, by working with pneumatic conveying machine manufacturers you can determine the best solutions.

4️⃣ Market Research and Competitor Analysis 🔍

Who are your competitors? Pneumatic conveying vs. By looking at comparisons like mechanical conveying you can develop the best solutions on the market.

Legal Processes for Pneumatic Conveying Factory 📜

The pneumatic conveying systems license and legal requirements process includes the following steps:

✅ Obtaining an environmental impact analysis and industrial production certificate

✅ Engineering approvals for pneumatic conveying systems

✅ Benefiting from tax advantages and incentives

Developing sustainable production strategies in these processes can increase your factory’s competitive advantage by using green energy solutions. 🌱⚡

How to Increase Efficiency in Pneumatic Conveying Systems? 🚀

When you set up a pneumatic conveying systems factory, energy efficiency and optimization of operational processes are of great importance. Here are some strategies:

📌 Reduce energy consumption by using low-pressure pneumatic conveying lines.

📌 Work with pneumatic conveying machine manufacturers to integrate the latest technologies.

📌 Standardize maintenance processes in pneumatic conveying systems.

Conclusion: Invest in the Technology of the Future by Building a Pneumatic Conveying Factory! 🏆

Establishing a pneumatic conveying systems factory offers a long-term profitable and innovative investment opportunity. It is becoming an increasingly preferred sector among industrial investors and production managers for those who want to establish a pneumatic conveying factory.

Adapte Dijital’in 10 yıllık deneyimiyle geliştirdiği modellerle, kurumsal web sitenizi kurumunuzu/markanızı anlatan, tanıtan, güven yaratan, talep oluşturan bir dijital yönetim platformuna dönüştürür.

Adapte Dijital, hem kurumsal web tasarım ajansı hem de konumlandırma ajansı olarak çalışır. Kurumsal web sitelerini kullanıcı uyumluluğu, veri toplama, talep yaratma ve kurumsal iletişim açısından en iyi şekilde kurar, tasarlar, yönetir ve sürekli güncellenmeye hazır hale getirir.

If you want to plan a factory setup and develop pneumatic conveying solutions in industry, you can achieve success with the right equipment selection, investment cost optimization and efficiency increase strategies! 🚀

🔹 You can get support from experts to get more information about Establishing a pneumatic conveying system manufacturing factory.

🔹 Contact industry leaders to get an offer about pneumatic conveying system prices and investment details!

📢 Take action now and take your place in the pneumatic conveying sector! 🎯

Pneumatic What is Transportation and Why is it Preferred? 🤔

Pneumatic conveying systems are a modern and efficient industrial conveying solution that transports materials from one point to another using air pressure or vacuum. Today, it is preferred in many sectors such as cement conveying systems, plastic granule conveying systems, food sector pneumatic conveying solutions and chemical industry pneumatic conveying. Establishing a pneumatic conveying system factory is a high-yielding venture for industrial investors. However, in order to establish a pneumatic conveying system manufacturing factory, it is first necessary to understand how these systems work and why they are preferred. Here are the advantages of pneumatic conveying systems and their role in the industry!

Basic Working Principle of Pneumatic Conveying Systems 🔬

Pneumatic conveying systems transport materials in closed pipelines with the help of air flow. The pneumatic pipe conveying process involves moving materials from one point to another by pulling them with pressurized air or vacuumis realized by being carried out. These systems offer ideal solutions, especially for transporting sensitive or powdery materials.

📌 Vacuum conveying systems are suitable for sensitive materials and are often used in the food and pharmaceutical industries.📌 Pressurized pneumatic conveying systems are effective for transporting high-volume materials and are common in the cement, plastics and chemical industries.

📌 Pneumatic conveyor systems can be easily integrated into different production lines with their flexible and modular design.

The advantages of these systems also make them stand out in terms of low maintenance costs, hygienic transportation and environmental sustainability.

Advantages of Pneumatic Conveying Systems 🚀

One of the biggest advantages of pneumatic conveying systems is that they prevent dust and dirt formation due to closed circuit operation and thus provide hygienic transportation. This feature is particularly important for food sector pneumatic conveying solutions and the pharmaceutical industry.

🔹 Requires less maintenance – Pneumatic conveying systems contain fewer moving parts compared to mechanical conveying systems, which reduces maintenance costs.

🔹 Modular and flexible structure – Pneumatic pipe conveying systems can be easily integrated into production processes and adapted to different lines.

🔹 Provides energy efficiency – Industrial pneumatic solutions provide environmentally friendly conveying with less energy consumption offers.

Especially in logistics and warehouse management processes, establishing a pneumatic conveying systems factory will be a highly efficient and low-cost investment.

Comparison of Pneumatic Conveying and Mechanical Conveying ⚖️

Pneumatic conveying vs. When compared to mechanical transport, pneumatic systems provide a great advantage in that they take up less space, have a flexible design and operate in a closed system. Pneumatic conveying systems have the following advantages compared to mechanical systems:

✅ Takes up less space – Pneumatic pipe conveying systems can be easily installed even in narrow spaces.

✅ More hygienic – Powder and granule conveying systems are protected from external factors by operating in closed pipes.

✅ Safer – Pneumatic conveying systems have fewer moving parts, which reduces work accidents.

However, mechanical systems may be more advantageous in transporting high volume and heavy materials. Therefore, when calculating the pneumatic conveying systems investment cost, the type and capacity of the material to be transported should be taken into consideration.

Technologies Used in Pneumatic Conveying Systems 💡

Establishing a pneumatic conveying factory requires gaining a competitive advantage by using the latest technologies. Today, pneumatic conveying machine manufacturers are developing systems that increase energy efficiency and consume less air.

🔸 Smart sensors and automation systems ensure the efficient operation of pneumatic conveying lines.

🔸 Low-pressure pneumatic conveying lines minimize energy consumption and reduce operating costs.

🔸 High-efficiency compressors, ensure that pneumatic conveying systems are more sustainable.

Investors who want to establish a pneumatic conveying factory can gain a competitive advantage and increase their market share by integrating the latest technologies. Industrial investors in particular can become leaders in the sector by developing industrial pneumatic solutions.

Pneumatic conveying systems are one of today’s most innovative conveying technologies and are increasingly preferred in the industrial sector with their high efficiency, hygienic conveying and energy saving advantages. If you have an investment plan such as establishing a pneumatic conveying system manufacturing factory, you can realize a successful venture by conducting market research and using the best technologies. 🚀

Pneumatic Conveying System Installation Process and Costs 💰

Establishing a pneumatic conveying system factory is a process that requires proper planning and investment. Establishing a pneumatic conveying system manufacturing factory is a comprehensive undertaking that includes not only technology investment but also logistics, engineering and legal processes. For industrial investors, many factors such as energy efficiency, operational costs and market demands should be taken into consideration. Here’s what you need to know about pneumatic conveying systems investment costs and installation stages!

1️⃣ Necessary Components and Technologies for Pneumatic Conveying Systems 🔧

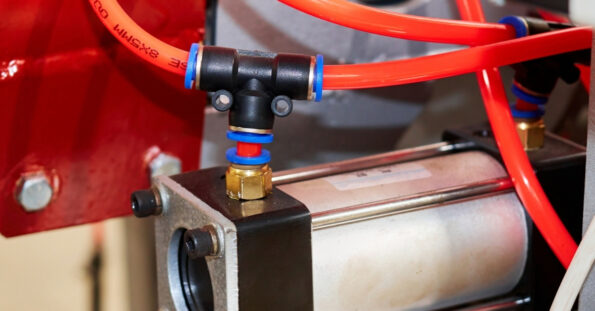

Pneumatic conveying systems consist of technological solutions that offer high-efficiency transportation and operate in a closed system. Pneumatic pipe transport provides material movement with air flow, while pneumatic conveyor systems offer integrated solutions with high capacity.

📌 Vacuum conveying systems – Used for transporting lighter and more delicate materials. Food sector pneumatic conveying solutions are equipped with this technology.

📌 Pressurized pneumatic conveying systems – Ideal for transporting denser and larger volumes. Cement conveying systems and chemical industry pneumatic conveying systems fall into this category.

📌 New generation systems developed by pneumatic conveying machine manufacturers increase energy efficiency with lower air consumption.

The compressors, air filters, pneumatic pipes and valve systems used in pneumatic conveying systems are the most critical components in the installation process. Entrepreneurs who want to establish a pneumatic conveying factory can create a more profitable business model in the long term by investing in high-quality and durable equipment.

2️⃣ Pneumatic Conveying System Investment Cost and Financing Options 💸

Establishing a pneumatic conveying systems factory requires a high amount of capital at the beginning. However, pneumatic conveying systems investment cost is a high-return investment in the long run compared to operating costs.

💰 Pneumatic pipe conveying systems investment items:

🔹 Purchasing machinery and equipment – Pneumatictransportation machines are systems that must be high quality and long-lasting.

🔹 Infrastructure and factory installation – In order to establish a pneumatic conveying system manufacturing factory, investment in industrial infrastructure is required.

🔹 Energy costs – Entrepreneurs who want to establish a pneumatic conveying factory can reduce operating costs by choosing systems with low energy consumption.

🔹 Maintenance and spare parts expenses – Periodic maintenance programs recommended by pneumatic conveying machine manufacturers should be implemented.

At this point, investors can benefit from government incentives and They can benefit from industrial loans. Industrial investors can increase their business efficiency by investing in logistics and warehouse management solutions.

3️⃣ Things to Consider in Pneumatic Conveying System Installation 🚀

Establishing a pneumatic conveying systems factory is not limited to equipment purchase and installation. There are some critical stages for a successful system integration.

✅ Determine system capacity – Solutions suitable for different applications such as cement conveying systems, plastic granule conveying systems or powder and granule conveying systems should be selected.

✅ Energy efficiency analyses should be performed – Pneumatic conveying systems investment costs should be optimized with low energy consuming systems.

✅ Designs that offer ease of maintenance should be preferred – Pneumatic conveyor systems should include modular structures that provide easy maintenance.

✅ Legal regulations must be met – Those who want to establish a pneumatic conveying system manufacturing factory must comply with local and international industry standards.

Industrial investors can save labor and time by automating their operations with industrial pneumatic solutions.

4️⃣ Achieving Long-Term Profitability by Establishing a Pneumatic Conveying System 📈

Establishing a pneumatic conveying systems factory is a highly profitable venture with proper planning and strategic investment. Entrepreneurs who want to establish a pneumatic conveying factory can gain a competitive advantage by following the steps below:

🔹 Make the right sector selection – Pneumatic conveying systems can be used in different sectors such as food sector pneumatic conveying solutions, chemical industry pneumatic conveying or logistics and warehouse management.

🔹 Invest in high technology – Pneumatic conveying machine manufacturers are developing systems that consume less energy and are highly efficient.

🔹 Do market research – When calculating the investment cost of pneumatic pipe conveying systems, The requested capacity and service quality should be determined.

🔹 Increase operational efficiency – Pneumatic conveyor systems, supported by automation, save time in production processes.

Investors who want to establish a pneumatic conveying systems factory can establish a profitable and sustainable business by investing in correct planning, appropriate financing and modern technologies. 🚀

Necessary Machinery and Equipment for a Pneumatic Conveying System Manufacturing Factory ⚙️

Establishing a pneumatic conveying system manufacturing factory is not possible without the right selection of machinery and equipment. Pneumatic conveying systems have an infrastructure consisting of high-performance components and use technologies that increase production efficiency. Necessary for pneumatic pipe conveying systems machines should be determined according to the characteristics of the transported material and industrial needs. Here are the indispensable machines for those who want to establish a pneumatic conveying systems factory!

1️⃣ Compressor Selection for Pneumatic Conveying System 🔩

One of the basic components of pneumatic conveying systems is air compressors. Pneumatic conveying machine manufacturers aim to increase energy efficiency and performance by developing compressors with different pressure levels.

🔹 Oil-free air compressors – Ideal for food sector pneumatic conveying solutions and pharmaceutical industry applications.

🔹 Oil-lubricated air compressors – More durable for cement conveying systems and metal industry pneumatic conveying systems.

🔹 Low energy consumption models – Long-term savings in terms of pneumatic conveying system investment costs provides.

When selecting a compressor, pressure capacity, air flow rate and energy consumption should be taken into consideration. Industrial investors should determine the most suitable compressor type to establish an efficient pneumatic conveying system manufacturing plant.

2️⃣ Filter and Valve Systems for Pneumatic Pipe Transport 🏭

Pneumatic pipe transport systems have filter and valve mechanisms that regulate air flow and control material transport. Pneumatic conveyor systems are high-efficiency and low-maintenance systems.

📌 Air filters – Pneumatic conveying systems require high-precision filters to keep the materials conveyed by air clean.📌 Pressure regulators – Air pressure stabilizing systems are required for those who want to establish a pneumatic conveying factory.

📌 Automatic control valves – Pneumatic conveying machine manufacturers are optimizing their systems by developing valve technologies that consume less energy.

These equipments allow pneumatic conveying systems to work more efficiently and minimize energy costs.

3️⃣ Pneumatic Conveyor Systems and Automation 🚀

Pneumatic conveyor systems are used to transport materials to certain distances and work integrated with automation technologies. Those who want to establish a pneumatic conveying system manufacturing factory can invest in modern automation systems to create a more efficient production line.

✅ Vacuum conveying conveyors – Ideal for powder and granule conveying systems.

✅ Pressure pneumatic conveyors – Used to transport heavy materials over long distances.

✅ Industrial PLC systems – For those who want to establish a pneumatic conveying factory, fully automatic solutionsunar.

These systems are among the solutions that provide long-term efficiency for industrial investors. Pneumatic pipe conveying systems, when supported by automation offer more production with less labor.

4️⃣ Maintenance and Spare Parts Strategies for Pneumatic Conveying Systems 🔧

Establishing a pneumatic conveying systems factory does not end with just purchasing machinery and equipment. Maintenance planning is essential for long-term efficiency. Pneumatic conveying system investment costs can be reduced with the right maintenance strategies.

🔹 Periodic maintenance programs – Pneumatic conveying machine manufacturers recommend regular maintenance for longer-lasting machines.

🔹 Spare parts management – Pneumatic pipe conveying systems should have quick-changeable parts to minimize momentary failures.

🔹 Energy efficiency tests – Industrial investors can achieve cost advantages by selecting pneumatic conveying solutions with lower energy consumption.

Entrepreneurs who want to establish a pneumatic conveying factory can create a high-performance production process with regular maintenance and modern spare parts management.

Conclusion: Technology and Efficiency Should Be Priorities for a Pneumatic Conveying System Manufacturing Factory

Establishing a pneumatic conveying systems factory can turn into a profitable venture with the right investments in technology. Pneumatic conveying machine manufacturers develop systems that consume less energy and perform higher offer long-term solutions for investors.

💡 Pneumatic pipe conveying systems provide great advantages for industrial investors when supported by automation and modern technology.💡 Pneumatic conveying systems produce solutions that require less labor and provide energy savings.

💡 Entrepreneurs who want to establish a pneumatic conveying system manufacturing factory can gain a competitive advantage with modern equipment and effective maintenance strategies.

Pneumatic conveying systems investment cost is optimized with the right machine selection and an efficient business model allowing you to gain a strong place in the industrial sector! 🚀

Ways to Increase Efficiency in Pneumatic Conveying Systems 🚀

Pneumatic conveying systems offer fast, efficient and safe material handling solutions in industrial production processes. Pneumatic pipe conveying systems are designed to reach maximum conveying capacity with minimal human intervention. However, factors such as energy consumption, maintenance processes and conveying efficiency are critical for industrial investors. Here are the most effective ways to increase efficiency for those who want to establish a pneumatic conveying systems factory!

1️⃣ Air Pressure Optimization for Pneumatic Conveying System ⚙️

Pneumatic taSince conveyor systems transport materials using air pressure correct air pressure setting is of great importance for efficiency. Incorrect pressure settings can increase the investment cost of pneumatic conveying systems and cause energy waste.

✅ Determining ideal air pressure: Pneumatic pipe conveying systems should operate with air pressure appropriate to the density and particle size of the material being conveyed.

✅ Pressure control systems: Pneumatic conveying machine manufacturers are increasing energy efficiency with smart pressure control technologies.

✅ Automatic air flow adjustment: Those who want to establish a pneumatic conveying system manufacturing factory should automatic adjustment suitable for variable loads and conveying distances should invest in systems.

Establishing a pneumatic conveying factory provides lower costs and higher conveying capacity with air pressure optimization.

2️⃣ Maintenance and Cleaning in Pneumatic Conveyor Systems 🛠️

Establishing a pneumatic conveying systems factory is not completed by purchasing the machines alone. Regular maintenance and cleaning are essential for an efficient system. Pneumatic conveying machine manufacturers recommend periodic maintenance to ensure the longevity of their systems.

🔹 Hose and pipe cleaning: Pneumatic pipe conveying systems can become clogged due to particles that accumulate over time. Regular cleaning optimizes air flow.

🔹 Filter replacement: Pneumatic conveyor systems should use high-performance filters to prevent dust and particles from accumulating in the system.

🔹 Wear detection: Those who want to establish a pneumatic conveying factory can minimize the risk of failure by regularly checking the wear in the compressor and air ducts.

Maintenance and cleaning reduce the investment cost of pneumatic conveying systems and ensure that the system operates more efficiently.

3️⃣ Automation Technologies to Set Up a Pneumatic Conveying Factory 🤖

Setting up a pneumatic conveying factory offers higher efficiency when supported by modern automation technologies. Pneumatic conveying machine manufacturers are developing automation solutions that save energy and reduce labor.

✅ Smart sensors: Those who want to establish a pneumatic conveying system manufacturing factory can make processes more efficient with sensors that optimize air pressure and material flow.

✅ PLC control systems: Pneumatic conveyor systems can operate without the need for operator intervention thanks to fully automatic software.

✅ Remote monitoring and control: Pneumatic pipe conveying systems can be remotely managed with smart IoT technologies and provide instant efficiency analyses can be done.

Industrial investors who want to establish a pneumatic conveying factory can gain cost advantages in the long term with automation investments.

4️⃣ Energy Efficiency Strategies for Pneumatic Conveying Systems ⚡

Establishing a pneumatic conveying systems factory also requires optimizing energy consumption. Pneumatic conveying systems investment costs can be reduced with efficient energy management.

🔹 Low energy consumption compressors: Pneumaticmatic conveying machine manufacturers support systems with high-performance motors that consume less energy.

🔹 Pressure recovery systems: Those who want to establish a pneumatic conveying system manufacturing factory can save energy by reusing air pressure.

🔹 Timer and automatic shutdown systems: Pneumatic conveyor systems only work when needed and do not consume unnecessary energy.

Energy-saving pneumatic pipe conveying systems significantly reduce operating costs and provide sustainable production in the long term.

Conclusion: Smart Investments Are a Must for Maximum Efficiency in Pneumatic Conveying Systems

Investors who want to establish a pneumatic conveying factory can maximize system efficiency by using the right technology and strategies.

💡 To reduce the investment cost of pneumatic conveying systems, energy-saving machines and automation systems should be preferred.

💡 Pneumatic conveying systems, regular maintenance and It works longer with air pressure optimization.

💡 Pneumatic conveying machine manufacturers provide great convenience in the industrial sector by developing smarter and more efficient systems.

Establishing a pneumatic conveying system manufacturing factory can turn into a profitable business model with the right investments and planning. Pneumatic pipe conveying systems equipped with smart solutions provide a competitive advantage in the industrial sector and accelerate business processes! 🚀

Conclusion and Recommendation: Digital Transformation in Pneumatic Conveying Systems with Adapte Dijital 🚀

Establishing a pneumatic conveying factory provides a great competitive advantage with the right strategies and technological investments. However, just installing quality machines and systems is not enough. It is critical to exist in the digital world, develop a strong online sales strategy and receive professional digital marketing support to reach the target audience. At this point, Adapte Dijital is here to support the growth of businesses in the pneumatic conveying systems sector!

🔹 Take your pneumatic conveying systems investment to the online world!

🔹 Stand out in search engines, reach your target audience!

🔹 Benefit from the power of digital marketing in pneumatic conveying systems sales!

Adapte Dijital offers SEO, Google Ads, web design and content services specifically for companies operating in the pneumatic conveyor systems and pneumatic pipe conveying systems sectors. marketing services. To accelerate your digital transformation contact us now and make a difference in your sector!

Also, you can check out our article for more information on selling pneumatic conveying systems: 👉 Selling Pneumatic Conveying Systems