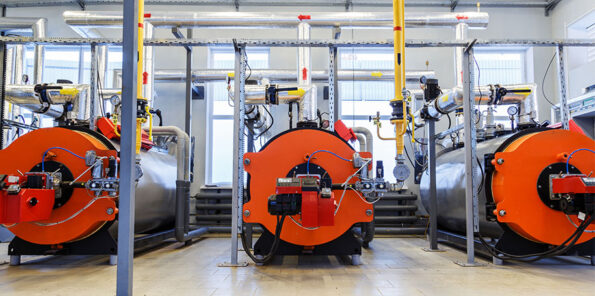

Establishing a liquid and gas fuel boiler production facility is an highly profitable industrial investment. However, entrepreneurs who want to enter this field need to analyze the technical requirements, legal processes and market dynamics well. Planning the stages from production to marketing correctly ensures that the factory is efficient, sustainable and competitive. As Adapte Digital, we support investors in increasing their success in this field with our expertise in digital transformation and business development processes. If you also want to grow in the energy sector and gain a competitive advantage, you should carefully examine the following steps. 🚀

One of the most important steps in establishing a liquid and gas boiler production facility is market analysis. Determining which types of boilers are in higher demand and which regional and international markets have growth potential shapes the direction of the investment. For example, in the European Union countries, the demand for more environmentally friendly and low-emission boilers is increasing rapidly. In Türkiye, high-capacity boilers are preferred more for industrial facilities, hotels and large housing projects. Investors should plan their production line correctly and create their product range in line with customer expectations based on these market analyses. 📈

Another important issue to consider during the production process is quality standards and certification processes. ISO 9001, CE certificate and energy efficiency certificates are required for the both domestic and foreign market acceptance of the produced boilers. Boilers that pass safety and durability tests increase customer satisfaction by providing long-lasting use. Especially considering that gas-fired boilers operate at high pressure, safety tests and engineering calculations are of vital importance. Boilers with high combustion efficiency, low fuel consumption and environmentally friendly technologies provide a market advantage and enable you to differentiate yourself from your competitors.

Finally, one of the ways to increase the profitability of your production facility is to determine the right marketing and sales strategies. Today, B2B marketing channels, digital advertising strategies and international trade networks are of great importance to gain customers. For example, as a boiler manufacturer, you can become more visible on Google by strengthening your website with SEO-compatible content. In addition, you can establish direct contact with large buyers using professional networks such as LinkedIn and industrial fairs. 🌍 As Adapte Digital, we help businesses strengthen their digital presence and compete in international markets. If you want to establish a liquid and gas fuel boiler production facility, you can gain a competitive advantage by optimizing your digital transformation and market strategies. 🚀

İçindekiler

ToggleWhat to Know Before You Start Liquid and Gas Fuel Boiler Production Requirements

For entrepreneurs who want to establish a liquid and gas fuel boiler production facility, starting with the right strategy is of great importance. 🚀 In this process, you need to consider many factors from market analysis to financing, from legal processes to production line planning. As Adapte Digital, we help you grow your business efficiently and sustainably with our digital consulting expertise. So, what should you pay attention to before entering this sector?

Sector Analysis: Fuel Boiler Production Market and Competition Status

Liquid and gas fuel boilers have a wide range of uses from industrial facilities to residential projects. Therefore, it is very critical to determine in which segments there is demand before entering the market. 🔍 For example, While industrial facilities and hotels in Turkey tend to use high-capacity fuel boilers, European and US markets prefer more environmentally friendly and low-emission fuel boilers. If you plan to export, you have to produce models that comply with the EU’s strict environmental standards.

Analyzing the competition is the best way to determine the opportunities the market offers you. You can make yourself more competitive by examining the products, pricing policies and marketing strategies offered by rival companies in detail. At this stage, it is a great advantage to examine your competitors’ online visibility and customer feedback using digital analysis tools. 📊

Capital and Financing Resources Required for Fuel Boiler Production

One of the most important stages of establishing a fuel boiler production facility is capital planning. Many cost items such as machinery investments, raw material supply, factory infrastructure and employee salaries affect the payback period of the investment. 💰

The amount of capital required to set up an average production line varies depending on production capacity, technology used, and market targets. For example, an investment of around 2-5 million TL may be sufficient for a low-capacity workshop-type production line, while a budget of 50 million TL or more may be needed for a large-scale factory.

If you want to lighten your financial burden, you can receive grants and incentives from institutions such as KOSGEB, TÜBİTAK, and Development Agencies. In addition, it is possible to get loans from banks with suitable interest rates for industrial investments. 📈 Supporting your investment with the right financial model increases your profitability and accelerates your growth in the long term.

Legal Permits and Documents You Must Obtain Before Establishing a Production Facility

In a sector with technical requirements such as fuel boiler production, legal compliance is of vital importance. To avoid risking your investment, you should obtain the necessary permits in advance. ✅

In the first stage, you may need to obtain a production permit from the Ministry of Industry and Technology and an environmental impact assessment report (EIA) from the Ministry of Environment. In addition, documents such as operation license, work safety documents and energy efficiency certificates must be completed before starting production.

However, in order for the fuel boilers you plan to produce to be accepted in the international market, they must have quality certificates such as CE, ISO 9001 and EN 303-5. These documents both increase customer confidence and make it easier for you to export. 🌍 Paying attention to these processes to produce quality and reliable production will ensure that your brand gains a strong place in the sector in the long term.

If you also want to make a strong entry into the fuel boiler production sector, you can make a successful start by making the right market analysis, planning your financial resources effectively and completing the legal processes completely. 🚀 As Adapte Digital, we support you with business development and digital marketing strategies, helping you make your investment the most efficient!

Are you looking for a professional website to effectively promote your fuel boiler production service? Make a difference in the digital world with Adapte Digital’s expert Web Design Agency and Site Solutions! Present your services in the best way with modern and user-friendly web design.

You can get detailed information by watching our founder Gürbüz Özdem’s Web Design: Professional Image Construction video.

Fuel Boiler Production Plant Installation: Factory Planning and Technical Requirements

When setting up a liquid and gas boiler production plant, factory planning and determining the technical requirements correctly ensures that the investment is profitable and efficient in the long term. 🏭 Wrong location selection, inadequate machinery or deficiencies in logistics planning can disrupt production processes and increase costs. Therefore, moving forward with the right strategy is a critical step. As Adapte Digital, we help entrepreneurs establish successful factories with our expertise in digital business development and industrial transformation processes. 🚀

Selecting the Area for Fuel Boiler Production: Location and Infrastructure Factors

One of the most important factors in the success of a production facility is the right location selection. 📍 The factory’s infrastructure, proximity to raw materials, logistics advantages and energy costs directly affect production efficiency.

Basic factors to consider when choosing a location These are:

✅ Located in industrial zones: OSB (Organized Industrial Zones), provide tax advantages, low energy costs and logistical conveniences.

✅ Proximity to transportation networks: Proximity to main roads, ports and railway lines is a critical advantage for the transportation of raw materials to the factory and the shipment of produced fuel boilers. 🚛

✅ Energy and infrastructure access: Fuel boiler production is an energy-intensive process. The factory’s strong electrical infrastructure and gas connection ensures uninterrupted production processes. ⚡

A wrong location choice can complicate the production process by increasing logistics costs. Therefore, a detailed feasibility study should be conducted in the first stage and the most suitable industrial zone should be determined.

Selection of Machinery and Equipment to be Used in Production

Fuel boiler production is a process that requires precision engineering. 🏗️ Therefore, the high technology of the machines to be used in the factory directly affects the production quality and efficiency.

Basic production machines are:

🔹 Sheet metal cutting and bending machines – Required to create the body of the fuel boiler.

🔹 Welding robots and welding machines – For the production of durable and long-lasting fuel boilers is essential.

🔹 Automatic assembly lines – Accelerate the production process and minimize human errors.

🔹 Pressure test systems – Ensure that the safety tests of the fuel boilers produced are performed. 🔍

The most important points to consider when investing in machinery:

✔️ Efficiency and energy-saving machines should be preferred.

✔️ Dependency on human power should be reduced with automation systems.

✔️ Long-term maintenance agreements should be made with machine manufacturers.

In this process, You can make your production facility more efficient by using industry 4.0 applications and integrate remote monitoring and control systems with IoT technologies. 🌍

Logistics and Supply Management for an Efficient Production Process

One of the factors that determine the success of your production facility is effective supply and logistics management. All stages from raw material supply to production process, from shipping to stock management need to be optimized. 📦

🚛 Things to consider in logistics planning:

✔️ Timely and uninterrupted supply of raw materials

✔️ Delivery of manufactured fuel boilers to customers safely and quickly

✔️ Reducing costs by managing storage processes well

🔍 Effective supply chain management both reduces costs and prevents interruptions in production. For example, if sheet metal, insulation materials and electronic components are not delivered to production without interruption, factory downtimes may occur. This prolongs order delivery times and negatively affects customer satisfaction.

If you are planning to establish a liquid and gas fuel boiler production facility, you can gain a strong place in the sector by choosing the right factory location, using the best machines and managing your supply chain perfectly.

Quality Standards and Things to Consider in the Production Process

In the production of liquid and gas fuel boilers, quality standards and meticulous management of production processes increase the competitiveness of the products in the market and are one of the basic elements of ensuring customer trust. 🔍 It is of great importance to comply with the standards determined to produce durable, energy-efficient and environmentally friendly fuel boilers. At the same time, complete certification processes will increase sales and export opportunities not only in the local market but also in the international arena. 🚀

Mandatory Standards and Certification Processes for Liquid and Gas Fuel Boilers

Fuel boiler production is subject to certain regulations regarding safety since it involves systems operating with high pressure and flammable gases. 📜 Without certification and quality documents, it becomes difficult to compete in the market, and in some countries, sales permits cannot even be obtained.

Some of the mandatory quality and safety certificates:

✅ CE Certificate: Required for exporting to European Union countries.

✅ ISO 9001: Indicates that production management systems are maintained in accordance with quality.

✅ EN 303-5: It is the quality standard applied in Europe for pellet and biomass fuel boilers.

✅ TS EN 12952/TS EN 12953: These are certificates that determine the safety and quality standards of industrial fuel boilers.

✅ TSE Certificate: In order to sell in the domestic market in Turkey is required.

Starting certification processes early in the production phase prevents loss of time and accelerates the sales process of products. In addition, companies targeting exports have a great advantage by complying with international regulations as well as local quality certificates. 🌍

Technological Approaches for Efficient and Environmentally Friendly Fuel Boiler Production

Today, efficiency and environmental sustainability are among the most important factors in fuel boiler production. Fuel-fired boilers with low emission values, less fuel consumption and high heat efficiency are preferred more in the industrial and residential sectors.

⚡ Innovative approaches that can be applied for environmentally friendly production are as follows:

✔️ Using burner systems with high combustion efficiency

✔️ Integrating waste heat recovery systems

✔️ Minimizing emissions with flue gas filtration technologies

✔️ Optimizing fuel consumption with digital automation systems

Especially for the European market, the production of fuel-fired boilers with low carbon emissions provides a great advantage in terms of making a difference in the market. 🌱 However, environmentally friendly production processes both strengthen brand perception and provide the opportunity to benefit from government incentives.

Testing, Control and Safety Measures: How Can You Improve Product Quality?

After the fuel boiler production is completed, testing and quality control processes must be carried out meticulously. 🔍 Even small errors made during production can lead to serious malfunctions and safety risks during operation of fuel boilers.

Things to consider during testing processes:

🏗️ Pressure Tests: High-pressure tests are applied to measure the durability of fuel boilers.

🔥 Combustion Efficiency Tests: Fuel consumption and emission values are measured and their compliance with standards is checked.

🛠️ Welding Controls: Welding processes performed during the production phase are inspected with X-ray and ultrasonic tests.

🔧 Electrical and Mechanical Tests: The operation of automation systems and safety sensors is tested is.

If quality control processes are not given enough importance, customer complaints may increase and the brand’s reliability may be damaged. ❌ Therefore, having post-production tests performed by expert engineers at every stage also provides an advantage in after-sales support processes.

A strong position in the market can be achieved by prioritizing certification, environmentally friendly technologies and safety tests during the production process. These factors are a critical key to success for companies that want to gain a competitive advantage in the sector and open up to international markets. 🚀

Making Your Fuel Boiler Factory Profitable: Sales and Marketing Strategies

The success of a production facility is not limited to producing quality products. If the right marketing and sales strategies are not implemented, even the best production may not provide the expected return. 📈 In the intensely competitive boiler manufacturing sector, it is of great importance to correctly determine the customer base, use effective marketing methods and evaluate export opportunities.

Determining the Target Customer Audience for Local and International Markets

For fuel boiler manufacturers, determining the right customer audience forms the basis of marketing and sales activities. Focusing on the wrong customer segments can result in a loss of time and resources.

🔎 The target customer base can be determined according to the following segments:

✔️ Industrial Facilities: Large factories, production facilities and power plants prefer high-capacity fuel boilers.

✔️ Hotels and Residential Projects: Structures that need central heating systems tend towards medium-sized boilers.

✔️ Municipalities and Public Institutions: There may be large-scale boiler demands for district heating projects.

✔️ Export Markets: European and Middle Eastern markets are particularly interested in low-emission and environmentally friendly boilers. 🌍

After determining the customer base, it is necessary to develop promotion and marketing strategies suitable for the targeted sectors.

Increasing Kazan Sales with Digital Marketing, SEO and Advertising Strategies

In today’s world, digital marketing has become a determining factor even in B2B sales processes. 🔥 Companies operating in the industrial sector in particular should invest in SEO work to rank high in search engines.

📌 Digital marketing strategies:

✔️ SEO Compatible Website: Potential customers usually research manufacturers through Google. SEO studies should be conducted with keywords related to the sector such as “industrial boiler manufacturer”, “high efficiency boiler production”.

✔️ Google Ads and LinkedIn Ads: Advertising campaigns for companies operating in the industrial sector allow direct access to decision makers.

✔️ Digital Content Marketing: Content that attracts the attention of the target audience should be created with blog posts, technical documents and product comparisons.

✔️ Reference and Case Studies: Feedback and success stories of companies that have previously purchased boilers are a major factor in gaining the trust of new customers.

These methods, which increase digital visibility, accelerate the sales process and enable the brand to gain a reliable position in the sector. 🚀

Export Opportunities: The Process of Expanding to Global Markets

For liquid and gas boiler manufacturers, exporting is one of the most effective ways to increase profitability. 🌍 Especially in the European and Middle Eastern markets, the demand for quality and energy-efficient fuel boilers is increasing.

📢 Steps to follow when starting to export:

✔️ Target Market Selection: While European countries prefer environmentally friendly fuel boilers, the Middle Eastern market is turning to high-capacity industrial boilers.

✔️ International Certification: It is not possible to export to many countries without CE, ISO and other quality certificates.

✔️ Dealer Network and Distributorship Agreements: Creating a strong dealer and distributor network in the target market speeds up the sales process.

✔️ Participation in Fairs and B2B Events: International fairs are an important opportunity to increase brand awareness by communicating directly with potential customers.

In the digitalizing world, fuel boiler manufacturers should no longer be limited to traditional marketing methods, but should actively use digital channels to gain competitive advantage in export markets.

🔹 Determining the right customer base, using digital marketing strategies effectively and opening up to global markets are the most important elements that guarantee the sustainable success of your liquid and gas fuel boiler production facility. 💡

You can watch our founder Gürbüz Özdem’s Digital Consulting and Digitalization video for detailed information.

Services Offered by Adapte Dijital: The Key to Digital Success

To grow your brand in the digital world and gain a competitive advantage, you need effective strategies and the right partnership. Adapte Digital offers comprehensive solutions for businesses to achieve success in the digital world. We guide your brand’s digital transformation with the services we offer, from web design to digital marketing, from analytical reporting to consultancy. Here are the main services offered by Adapte Digital:

Professional Website Opening Service with Adapte Digital

Adapte Digital enables you to make a difference in the digital world by offering professional website opening service that suits your business’s needs. Whether you are a small business or a large company, we make it easy for you to reach your target audience with customized solutions 🌐. We ensure that your website reflects your brand identity and inspires trust in your customers with modern and user-friendly designs. Thanks to Responsive design, we aim for your site to work smoothly on all devices, be easily managed, and provide your visitors with a perfect experience with fast loading times.

Digital Marketing Strategies: Increase Your Visibility

To make a difference in your daycare and daycare business and the digital world, the right digital marketing strategies should be implemented. Adapte Digital develops customized marketing plans according to your brand’s needs. Social media marketing allows your business to have a strong presence on platforms like Facebook, Instagram, LinkedIn. Social media campaigns increase your brand awareness, enable you to interact with potential customers, and build brand loyalty.

With our SEO (Search Engine Optimization) services, we ensure that your website ranks high in search engines. We increase your organic traffic rate by using the right keywords, optimizing your content, and making technical improvements. Content marketing also attracts the attention of your target audience and increases interest in your brand by offering solutions to their problems. In addition, you can communicate regularly with your loyal customer base and inform them about your new products and services through email marketing.

Advanced Analytics and Reporting: Data-Driven Strategies

The way to be successful in the digital world is to make decisions data-driven. Adapte Dijital constantly monitors the performance of your business with advanced analytics tools and comprehensive reporting services. We analyze your website traffic, the impact of your social media campaigns, and the results of your digital marketing strategies and provide you with regular reports. This way, you can clearly see which strategies are effective, which areas you need to improve, and how you should proceed in the future.

With data-based analysis, you can determine the strengths and weaknesses of your business, optimize your marketing investments, and reach your goals faster.

Comprehensive Consulting and Continuous Support

As Adapte Digital, we are here to understand the needs of your business and offer you the right solutions. We are aware that every business has its own goals and challenges. Therefore, our expert consultants analyze the problems your business faces and help you develop your growth strategies. We are with you every step of the way, from strategic planning to implementation, from digital transformation to process optimization.

In addition, we respond to the changing needs of your business immediately by providing continuous support. We are always with you on issues such as website maintenance, social media management, campaign optimization or content updates.

Adapte Digital’s Success Stories: Meet Our References

With the comprehensive services offered by Adapte Digital, you can take your business to the next level in the digital world, expand your customer base and increase your brand awareness. Contact our expert team and turn your digital journey into a success!

Witness Adapte Digital’s success stories! To take a look at our projects that make a difference in the digital world and see how we ensure customer satisfaction, visit the Our References page now. Take your place for a powerful digital transformation!